Printing textiles with precision and expertise for over 20 years

Design becomes part of the fabric – durable colors, natural feel.

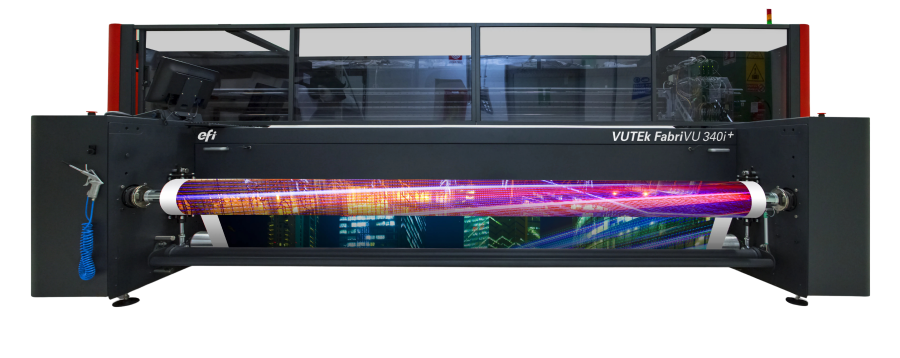

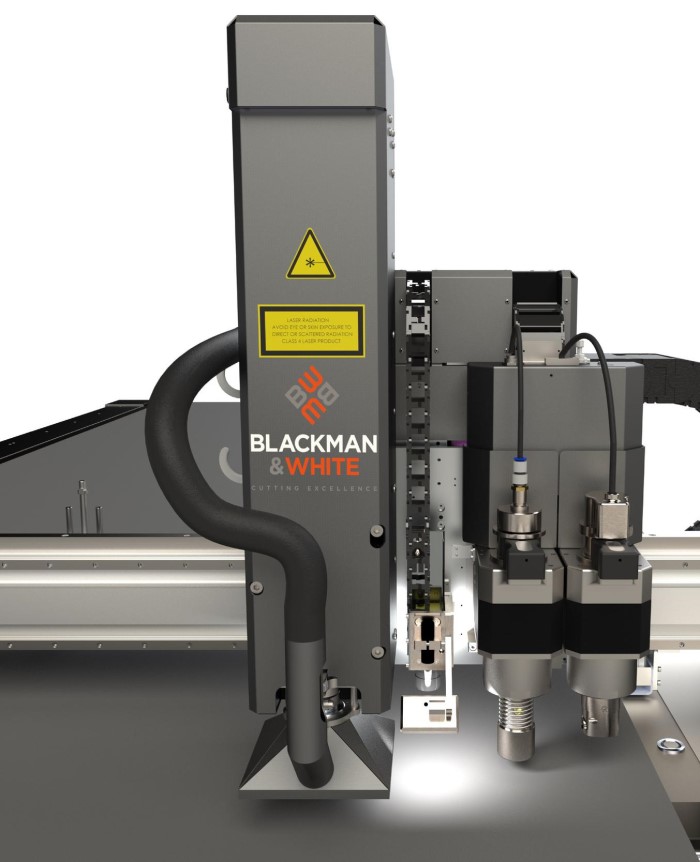

Professional-grade equipment

We operate five wide-format textile printers (3.2 m), including the EFI Vutek FabriVU 340i+ (water-based dye-sub), EFI Vutek FabriVU, ATP OneTex, and D.gen H12. Our workflow includes laser cutting (2 contour units), ultrasonic welding, and automated keder sewing PVC for perfect finishing.

100% local production

Faster turnaround, fair pricing, direct support.

End-to-end in-house processing

We print, cut, sew, and package everything in-house, with state-of-the-art industrial equipment.

This way we can guarantee consistency, quality and fast response time for every order.

Quality controlled

Each stage of production is monitored by our team: color profile, sewing, packaging.

We manually check each order before delivery.

Quality without compromise

Every textile we print reflects 20+ years of experience, precise technology, and attention to detail.

Controlling each step—material selection, color profiling, and finishing—allows us to guarantee vibrant, precise colors, flawless edges, and an impeccable brand image, irrespective of scale or environment.